2020 Industry, Regulatory, and Technology Trends Influencing the Machine Vision Systems Manufacturers Market

The global machine vision market is expected to grow by a CAGR of 6.5%, reaching a value of $14.7B, through 2025, according to a report by Markets and Markets. This growth is influenced by many factors, including new packaging methodologies, label regulations, and technology innovations. In this blog, we will discuss how smart packaging, FDA requirements, and the connected enterprise are influencing the global machine vision systems manufacturers market in 2020 and beyond.

Smart Packaging Methods

Companies in the consumer-packaged goods (CPG) industry including P&G and 3M are moving away from traditional methods of packaging and are trending towards smart packaging. Smart packaging allows customers to use QR codes to access additional information regarding the product while in the store, offer incentives for online product registrations, provide assembly/use instructions, verify product authenticity, and assure product quality. As well as improving the customer experience, smart packaging allows for easier recycling/disposal after the consumer throws away the packaging. This type of packaging creates opportunities for machine vision inspection both within organizations that already have vision systems and ones that do not. According to a study by Grand View Research the global smart packaging market is expected to grow by 8.9%, reaching a value of 6.65B by 2024.

FDA Label Requirement Changes

The FDA is implementing new requirements for labels placed both on food and drug products in 2020. These changes include adding more information to the nutritional facts and expiration areas of labels. These changes have already been implemented at the start of 2020. With companies now having to comply with the new FDA standards, there will be an increased need for automated inspection on labels to make sure that all labels are within the FDA spec.

Connected Enterprise and the IIoT

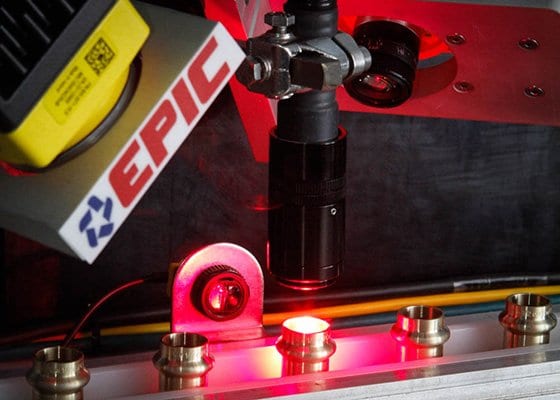

The global connected enterprise is expected to reach USD 1.94 trillion by 2025 at a CAGR of 35%, according to a report by Grand View Research. The connected enterprise is a broad term referring to the digitalization and networking of business operations. The connected enterprise improves agility, productivity, and process management. In the industrial world, the Industrial Internet of Things is making a big push. Having the ability to collect in-depth product and manufacturing data; transfer data from manufacturing operations to business operations, and report on this data all without human-to-human or human-to-computer interaction has shown to greatly increase production. Companies such as Siemens, Cognex, and Rockwell Automation all have product offerings allowing for a more connected plant and business operation. With the increase of smart manufacturing and connectivity, automated inspection systems will continue to evolve and become more prevalent at plants across the world.

Conclusion

The global machine vision systems manufacturers market will continue to grow. In fact, it is one of the fastest growing industrial markets today. Companies need to improve their product quality and increase productivity. New smart-packaging methods, FDA requirements, and the IIoT will influence this market through 2020 and beyond. If you are interested in implementing machine vision at your plant, get in touch with EPIC Systems at 314-806-1678 or by filling out a form.